| News | Date:2022-2-25 10:10:52 Publisher:Sumino Precision |

The extrusion biaxial stretching molding of plastic film generally adopts special equipment. The film formed by the extruder plasticized molten material is first stretched longitudinally, and then stretched transversely, so that the film blank is stretched and widened, and the process is achieved. The required film thickness is the biaxially oriented plastic film. The raw materials used in plastic film extrusion biaxial stretching include extrusion molding of resins such as polyvinyl chloride, polypropylene, polyester, polystyrene, polyethylene and polyamide.

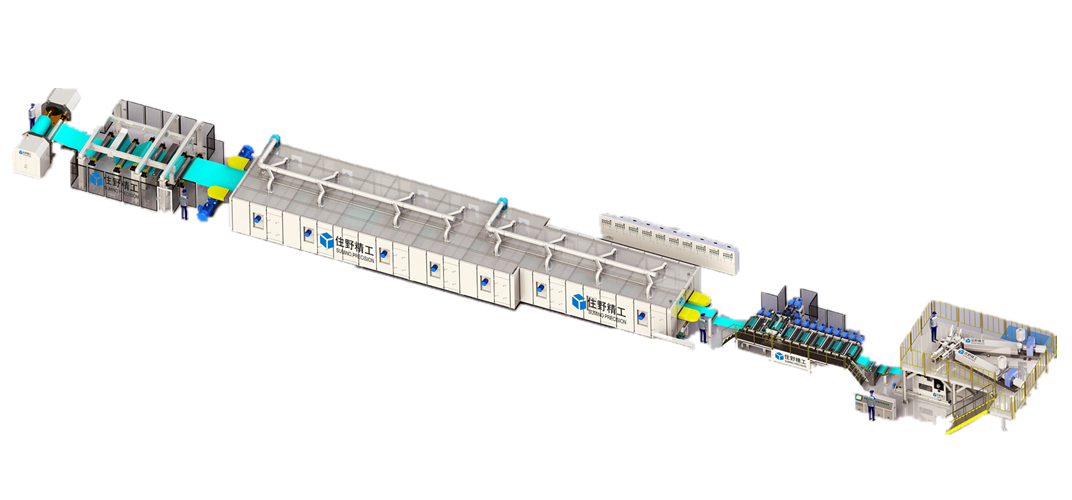

The production process is as follows: the screw extruder mixes the raw material and the plastic film → cools down the surface of the stick to measure the thickness → corona treatment → rewinds the biaxially oriented polypropylene film extrusion molding production line polypropylene resin and auxiliary materials are pressed The formula requirements are calculated into a molten state → extrude through a perforated plate and a filter screen to measure the thickness of a thickness gauge → longitudinal stretching → transverse equipment schematic diagram Refer to the drawing and mix evenly → single molding die extrusion → heat setting → trimming

Polypropylene film extrusion biaxial stretching molding Polypropylene film biaxial stretching molding is extrusion molding of polypropylene sheet (flat film) or tubular film with a certain thickness, in the state between the softening temperature and the melting temperature, along its After being stretched in the longitudinal and transverse directions (separately or simultaneously), it is made by shaping. Since polypropylene resin is a crystalline high polymer, when it is stretched under suitable temperature conditions, its molecules are rearranged, thereby improving or improving the mechanical properties of polypropylene films. For example, compared with ordinary polypropylene films, the crystallinity, tensile strength, impact strength, tear strength, grease resistance and bending life of biaxially oriented polypropylene films are significantly improved; in addition, the cold resistance, Heat resistance, transparency, air tightness, moisture resistance, gloss and electrical insulation are also improved compared to ordinary polypropylene film (CPP). It is used to produce biaxially oriented polypropylene (BOPP) films of various specifications with excellent mechanical and electrical properties, good cold resistance, air tightness and dimensional stability. BOPP film is an excellent packaging and insulating material, widely used in food packaging, opaque cold drink packaging, adhesive tape, capacitor film and synthetic paper.

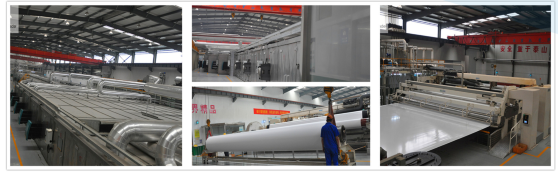

Nanjing Sumino Precision Machinery Co., Ltd. has a professional sheet production line. The company's main sheet machine manufacturing production lines include: PET/PRET sheet production line, PP sheet production line, PP vacuum profile extrusion production line, PP/PC vacuum sheet production line, PC/PP corrugated board production line, PVDF photovoltaic back sheet production line, PMMA acrylic sheet production line, PE waterproof membrane production line, high-performance barrier sheet production line, optical panel production line, multi-layer co-extrusion sheet production line, etc.

Company address: No. 11, Kaiyuan Road, Dongshan Bridge, Jiangning District, Nanjing City, Jiangsu Province

Contact: 025 5183 9686/133 9078 0291

Address: Nanjing Sumino Precision Machinery Co., Ltd., No. 11 Kaikai Road, Moling Street, Jiangning District, Nanjing

Web: www.susumino www.njsumino.com

Contact Sue

Whatsapp/Wechat : +86 17712413069